X-Ray inspection

TMH-novatecYour part 145 MROMore about TMH-novatec

TMH-novatec has over 30 years of expertise in the maintenance, repair, and overhaul (MRO) of engine parts and accessories for the aerospace industry. Our company will provide you with maintenance, repair, and overhaul (MRO) solutions for your commercial and military helicopter and aircraft parts and accessories. Through the years, our company has acquired an excellent global knowledge of aircraft and helicopter parts and accessories, and applies the best practices and industrial processes of the aviation industry market.

TMH-novatec is a certified PART / FAR 145 Repair Station. This allows us to supply FORM 1 certificates on the repaired products or components. Our company has received several Supplier Performance Awards from aviation key players for our top performance (100% On-time delivery and 0 non-quality) in maintenance, repair, and overhaul (MRO) of Commercial and Military Aircraft Engine parts. These awards highlight our excellent industrial operations and processes, supply chain management, and our best practices for maintenance, repair, and overhaul (MRO) operations. Flight safety and customer satisfaction are our daily concerns, and we are focused on providing you with the best service and support.

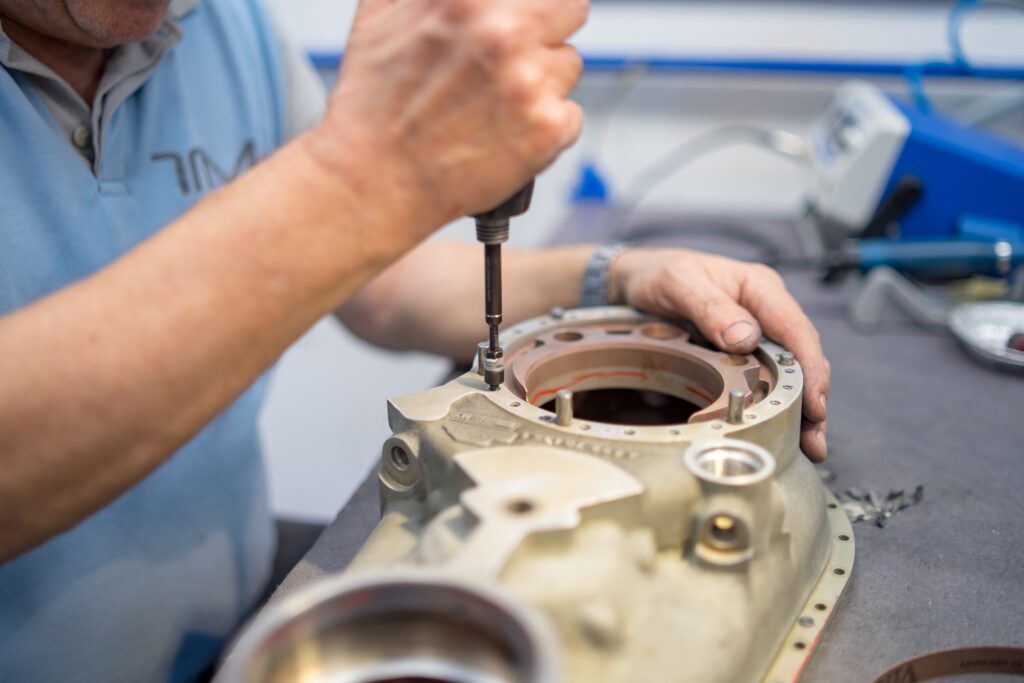

TMH-novatec has a long experience of helicopter and aircraft engine parts maintenance, repair, and overhaul (MRO). We have the in-house capabilities to clean, inspect and repair aircraft engine parts in accordance with the aircraft Engine Manual. For many years, we have invested in different processes to supply a complete Overhaul of your engine parts. For the cleaning of your products, we have become experts in chemical treatment, degreasing, and sandblasting processes. We also offer a number of processes to determine if the product can be released to service, if it is repairable or should be scrapped: visual inspection, X-ray inspection, as well as Fluorescent Penetrant Inspection (FPI). Finally, we can provide different solutions for part repair, such as chemical protection, machining, shot peening, welding, and painting. Our stock of consumables and products is managed by a strong supply chain in order to provide you with the shortest delivery time.

We work on different engines such as: GE90, CFM56, LEAP, M88, M53, TYNE, LARZAC, ARRIEL, ARRIUS, MAKILA, ARDIDEN,…

TMH-novatec also has an extensive experience of providing its customers with detailed Shop Finding Reports. Our proactive engineering department will advise you on how to lower the scrap rate of your products so that you can reduce your engine cost. A low scrap rate and short delivery time are both keys to ensure efficient maintenance, repair, and overhaul MRO services!

X-Ray inspection

TMH-novatecYour part 145 MROMore about TMH-novatec

Shot Peening

TMH-novatecYour Part 145 MROdecouvrir TMH-novatec

Fluorescent Penetrant Inspection (FPI)

Fluorescent Penetrant Inspection (FPI)

TMH-novatecYour Part 145 MROdecouvrir TMH-novatec