Fluorescent Penetrant Inspection (FPI)

Fluorescent Penetrant Inspection (FPI)

TMH-novatecYour Part 145 MROdecouvrir TMH-novatec

Radiography can be compared to photography but instead of using the light rays of the visible spectrum, this technology relies on X Rays. It allows us to see through an object or a structure at a specific point in time. As for photography, if the object moves during acquisition time, the image may be of poor quality, especially if the time of exposure is long.

Radioscopy can be compared to a video recording. Images are in motion and make it possible to see the part in real time.

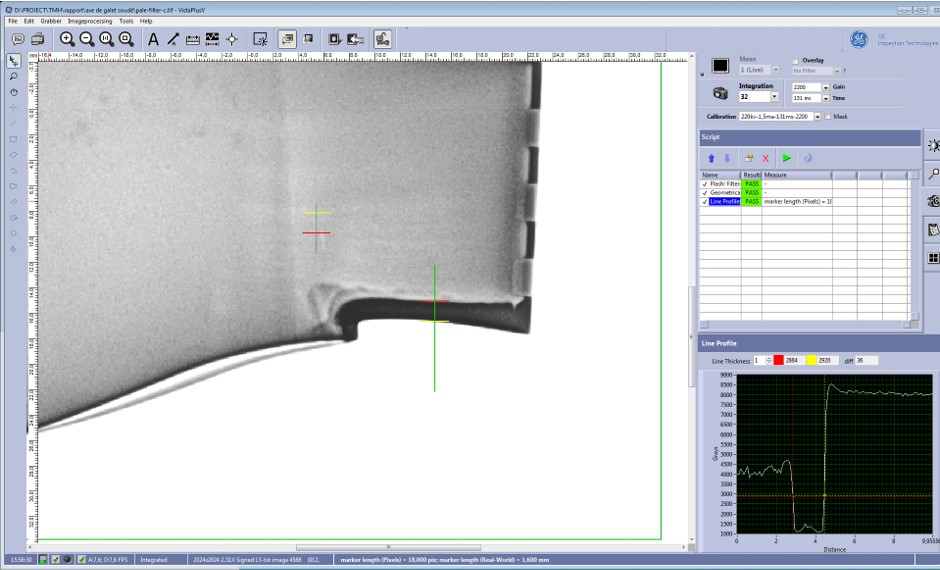

The X Rays or ionizing rays emitted by a generator go through the object. They are attenuated as they pass through different thicknesses and matter, until they reach a detector. This detector is composed of a large number of sensors that convert the received signal into electrical information and then into a grey scale image. Each sensor will represent an image pixel. The different scales of grey are linked to the ionizing ray paths and reveal the edges and porosities inside the parts.

Using this technology, we can inspect for cracks, as well as detect defects that cannot be otherwise detected without part destruction. This makes X Ray tests an essential tool for quality control, safety, and reliability.

TMH-novatec is equipped with a digital radioscopy / radiography system of the latest generation, the Phoenix X|CUBE v3 225kV model. This equipment is composed of a shielding booth, manipulators, an X ray tube, an X ray detector, a cooling pump, a control panel, and a control cabinet. It is used for nondestructive inspection of materials and parts in the field of manufacturing.

Capacity :

X Ray detector:

TMH -novatec offers several types of nondestructive inspection, with specific uses and benefits.

TMH-novatec uses two welding technologies that may be associated with X Ray inspection : TIG welding and Laser welding.

Our installation has been qualified by our aeronautical customers such as que Safran Helicopter Engines and Safran Power Units.

Our current qualifications :

In addition to civil and military aeronautics, our digital X Ray equipment is compatible with part inspection for the nuclear, space, automotive, and energy industries, and for any other industrial purposes.

Fluorescent Penetrant Inspection (FPI)

Fluorescent Penetrant Inspection (FPI)

TMH-novatecYour Part 145 MROdecouvrir TMH-novatec

Shot Peening

TMH-novatecYour Part 145 MROdecouvrir TMH-novatec