X-Ray inspection

TMH-novatecYour part 145 MROMore about TMH-novatec

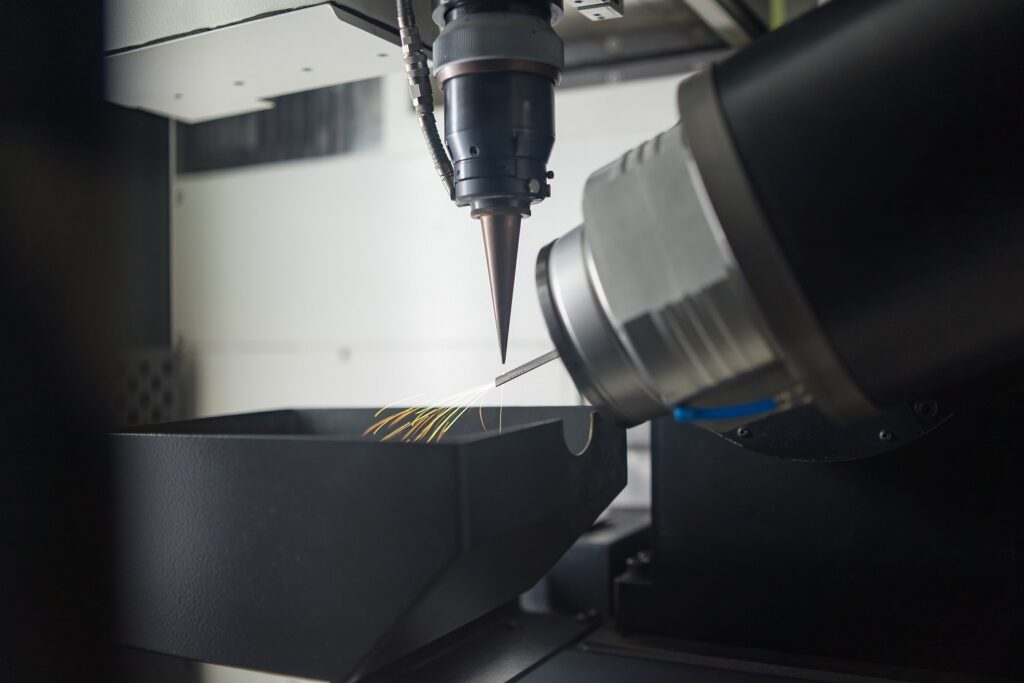

The laser (Light Amplification by Stimulation Emission of Radiation) process is based on the excitation of a source (gas, solids) that generates a beam with a given wavelength. For cutting, drilling, or welding, the beam must be absorbed by the material.

This process provides many advantages : High cutting and welding speed, low heating of material, low mechanical shrinkage (welding), high precision.

TMH-novatec has an extensive range of expertise on:

We are equipped with a 50 DMG Powerdrill 5 axes YAG laser machine with 300 W power.

Thanks to this machine, we can cut, weld and laser cut different metal materials (Steel, Stainless Steel, Inconel, etc.).

In order to perform these operations, our machine is equipped with a laser assist gas system. There are two available gasses:

The maximum part dimension is 500 mm X 500 mm X 700 mm. The maximum acceptable weight on worktable is 14 kilos.

The TMH-novatec laser process offer is completed by other processes:

Our laser installation has the following qualifications for drilling / cutting and laser welding :

In addition to civil and military aeronautics, our YAG laser machine is compatible with part manufacturing and assembly for the space, automotive and micromechanics industries or for any general industrial purposes.

X-Ray inspection

TMH-novatecYour part 145 MROMore about TMH-novatec

Fluorescent Penetrant Inspection (FPI)

Fluorescent Penetrant Inspection (FPI)

TMH-novatecYour Part 145 MROdecouvrir TMH-novatec